Starbucks Toyota Production System

The Toyota production system closely related to lean manufacturing has become the paragon for manufacturing across industries. Over decades Toyota operations have been streamlined thus resulting in the popularly known Toyota Production System TPS.

Analysis The Operations Management Of Starbucks Free Essay Example

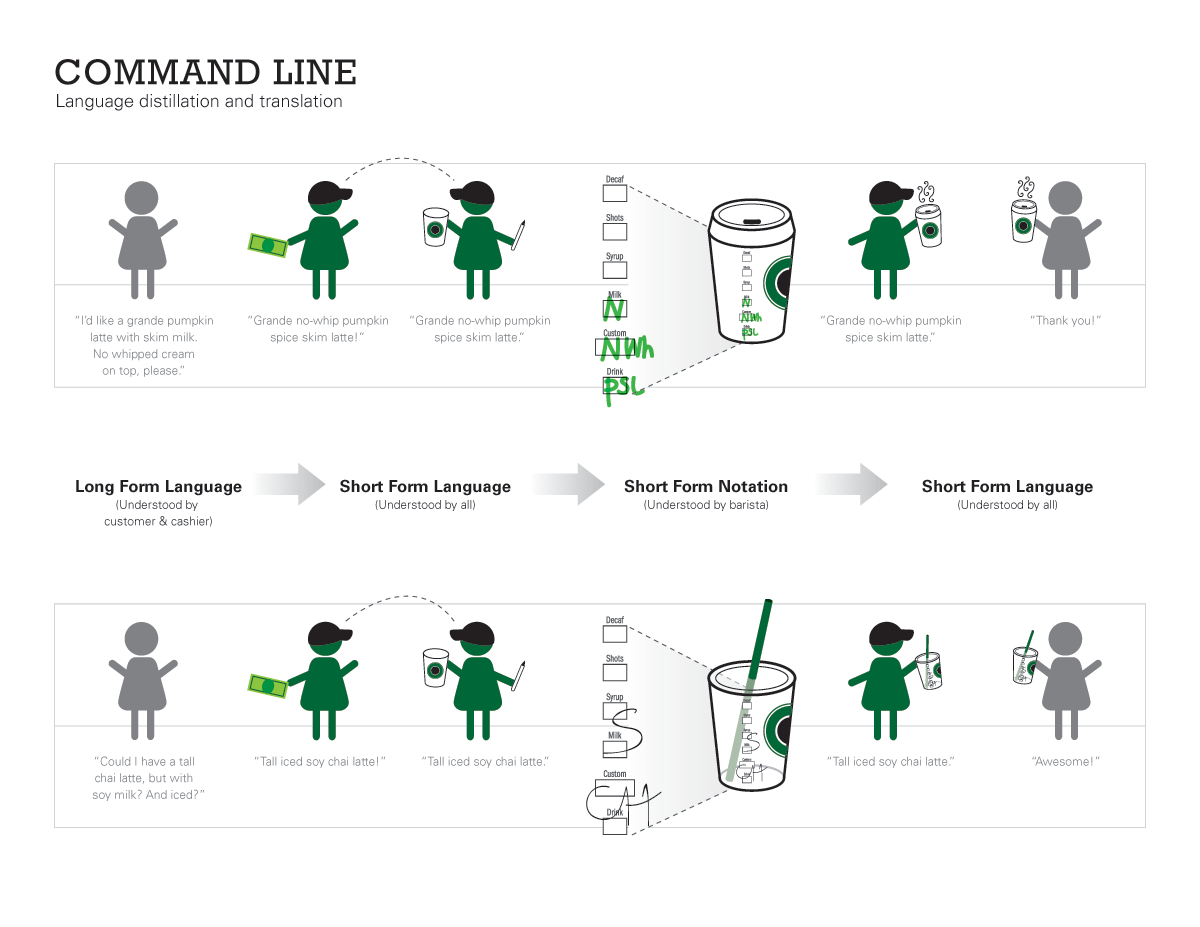

Todays Wall Street Journal article even mentions that Starbucks has a VP of Lean Thinking who is an acolyte of the Toyota lean manufacturing system.

Starbucks toyota production system. It is an original manufacturing philosophy that aims to eliminate waste and achieve the best possible efficiency what is often called a lean or just-in-time system. Potato Head toy that they challenge managers to put together and re-box in less than 45 seconds. Toyota revolutionized the technical side of lean production with the inclusion of product diversity into the production flow.

Potato Head assembly drills. The way we make vehicles is defined by the Toyota Production System TPS. Moreover once the new facility was up and running all of the US.

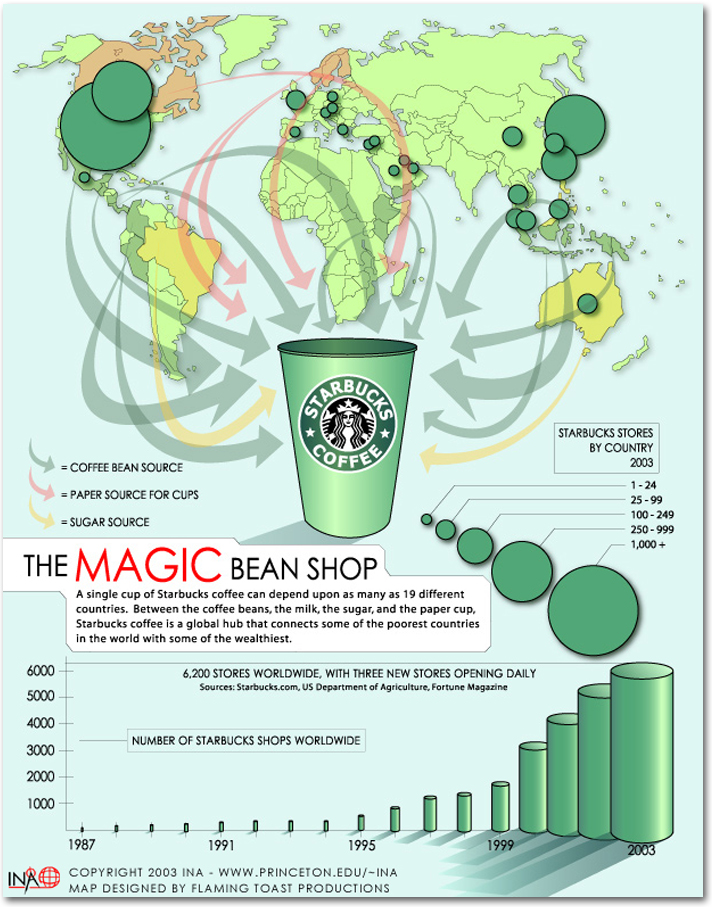

The Toyota production system is widely recognized for its groundbreaking. Regionalizing its coffee production allowed Starbucks to reduce its transportation costs and lead times says Gibbons. Coffee plants were able to switch from seven-day operations to five days.

The way we make vehicles is defined by the Toyota Production System TPS. When it comes to essential philosophies of lean management executives throughout numerous industries turn to Toyotas practices and production systems for guidance. But more importantly Toyota revolutionized the social dimension of work respecting workers brains as well as their hands.

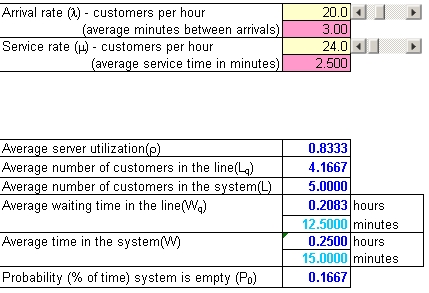

Starbucks Coffee Queueing Theory and Theory of Constraints. Similarly Toyotas supply chain structure and relations with suppliers has become a source of competitive advantage. Now the recipes can be delivered securely from the cloud to.

He and a 10-person lean team have been going from region to region armed with a stopwatch and a Mr. Built in 1992 Kent is the oldest plant in the company and just 13 miles away from the Starbucks Support Center. Beans are spoodled same sizes1 qtr batch 2 half batch etc directly into the grinder and then ground into small paper bag Contents of.

Pushing Starbuckss drive is Scott Heydon the companys vice president of lean thinking and a student of the Toyota production system where lean manufacturing got its start. The Kent Flexible Plant is the only plant with three ongoing manufacturing processes roasting the Starbucks and Seattles Best Coffee brands blending Teavana TMMC tea and a flexible soluble line for Starbucks VIA Instant. Specific Toyota initiatives may fall flat but Toyota is overall deserving of its reputation as a model of product flow.

Toyota may worry about how far an assembly line work must reach to grab a wrench while Starbucks is looking at how far the reach is for vanilla syrup but it is the same basic idea. Lean is originally used in Toyotas production system As soon as Starbucks start from MGT 353 at Universiti Putra Malaysia. The benefits of that approach were quickly apparent.

On the other hand the true power of the Toyota production system is the organizations ability to develop implement and share new knowledge. A Slower Starbucks Passes the Toyota Test. Pushing Starbuckss drive is Scott Heydon the companys vice president of lean thinking and a student of the Toyota production system where lean manufacturing got its start.

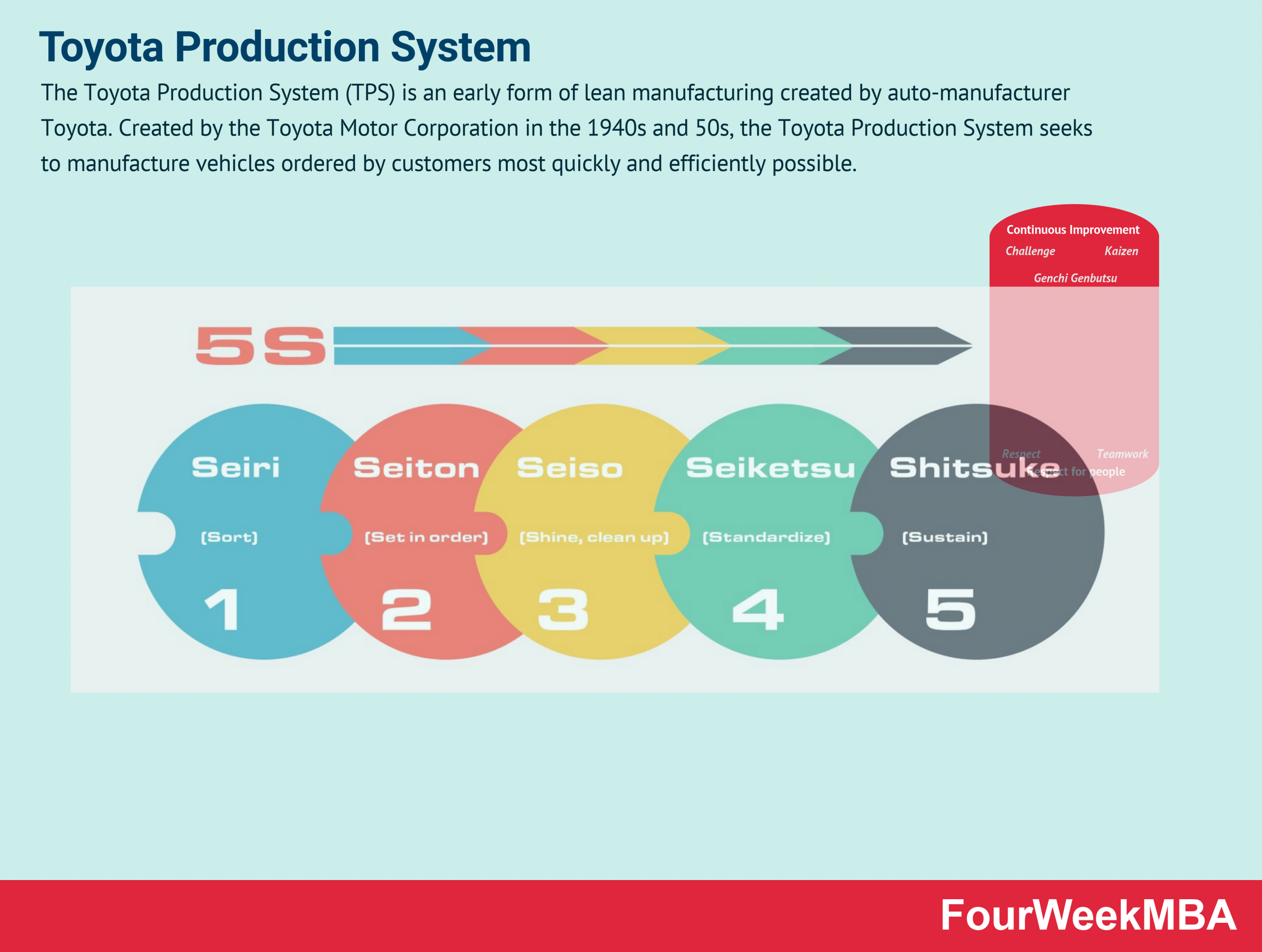

The Toyota Production System TPS is an early form of lean manufacturing created by auto-manufacturer Toyota. Embrace and adopt the principles of Toyotas Production System. If Starbucks coffee company adopted the Toyota Production System it will guarantee each cup of coffee be the best it can be no more burned coffee which is rare to find in Starbucks compared with other competitors.

Starbucks Corporation is a very profitable organisation earning in excess of 600 million in 2004. Most organizations need a burning reason to begin their lean journey. So factory workers become knowledge workers.

The company generated revenue of more than 5000 million in the same year. There are even Mr. The TPS was conceived when the company realized that producing massive quantities from limited product line to achieve maximum economies of scale led to.

In a nutshell Starbucks has a lean team that times baristas and teaches them aspects of Toyotas production system. The solution will also enable Starbucks to send new coffee recipes directly to machines which it has previously done by manually delivering the recipes to stores via thumb drive multiple times a year. Pushing Starbucks drive is.

It is a global coffee brand built upon a reputation for fine products and services. For Toyota the company that codified the Toyota Production System which was popularized in America as Lean began in World War II because they had no cash to pay for inventory. Created by the Toyota Motor Corporation in the 1940s and 50s the Toyota Production System seeks to manufacture vehicles ordered by.

Beans are now ground on demand in an exact amount for just the next brew batch just prior to brewing.

Will Starbucks Scrap Lean Manufacturing

Toyota Production System In A Nutshell Fourweekmba

Toyota Production System 5s Just Just In Time Kaizen

What Is Lean History And Early Development

Toyota 5 S System Scm 462 Dr Ron

Toyota Production System Tps Lean Principles Lean Thinking Lean Manufacturing Lean Six Sigma Business Process Management

Toyota Production System Kanban Production

Toyota Production System Cambio Organizacional Ingenieria Industrial Kaizen

Operations Management Toyota Free Essay Example

History Of The Toyota Production System Tps Lean Manufacturing

Toyota Production System Value Stream Map Example This Is A Complete Current State Value Stream Map You Can Improve This To Value Stream Mapping Map Streaming

Behind The Scenes At Starbucks Supply Chain Operations It S Plan Source Make Deliver Supply Chain 24 7

Toyota Production System Kanban Production

The Toyota Way Second Edition 14 Management Principles From The World S Greatest Manufacturer Amazon It Liker Jeffrey K Libri In Altre Lingue

Toyota Material Handling Production From Start To Finish

Tps House House Of Tps Toyota Production System House Toyota Production System Books Tps Book Industrial Engineering Lean Manufacturing Business Management

Post a Comment for "Starbucks Toyota Production System"